As a retailer with a more than 120-year history, J.C. Penney has navigated plenty of shifts in the retail space.

Today, the department store chain is focused on protecting its future since emerging from bankruptcy under new ownership in 2020. It's in the midst of a plan to invest more than $1 billion into its business by fiscal year 2025.

One of the central pillars of the retailer’s long-term improvement strategy is implementing more advanced technology, including AI and machine learning, into its supply chain operations.

Chief Information Officer Sharmeelee Bala, who joined J.C. Penney in January 2022, has been a key leader behind the company’s technology upgrade strategy, noting that such initiatives are now being looked at as enablers for the company rather than afterthoughts.

“J.C. Penney has been very strategic in ways to invest and how to invest and prioritize the investments in technology, especially,” Bala told Supply Chain Dive in an interview. She added that the company is focused on improving customer and employee experience through its technology investments.

On the customer side, Bala says J.C. Penney has begun implementing newer tools, some homegrown and others from third parties, across pricing and assortment planning, among other functions.

“We’ve also got investments where we decide the node from where we send, whether it was shipped from store or do we need to send it from a distribution center or a fulfillment center, which is closer to our customer, so that they can get it faster,” Bala said.

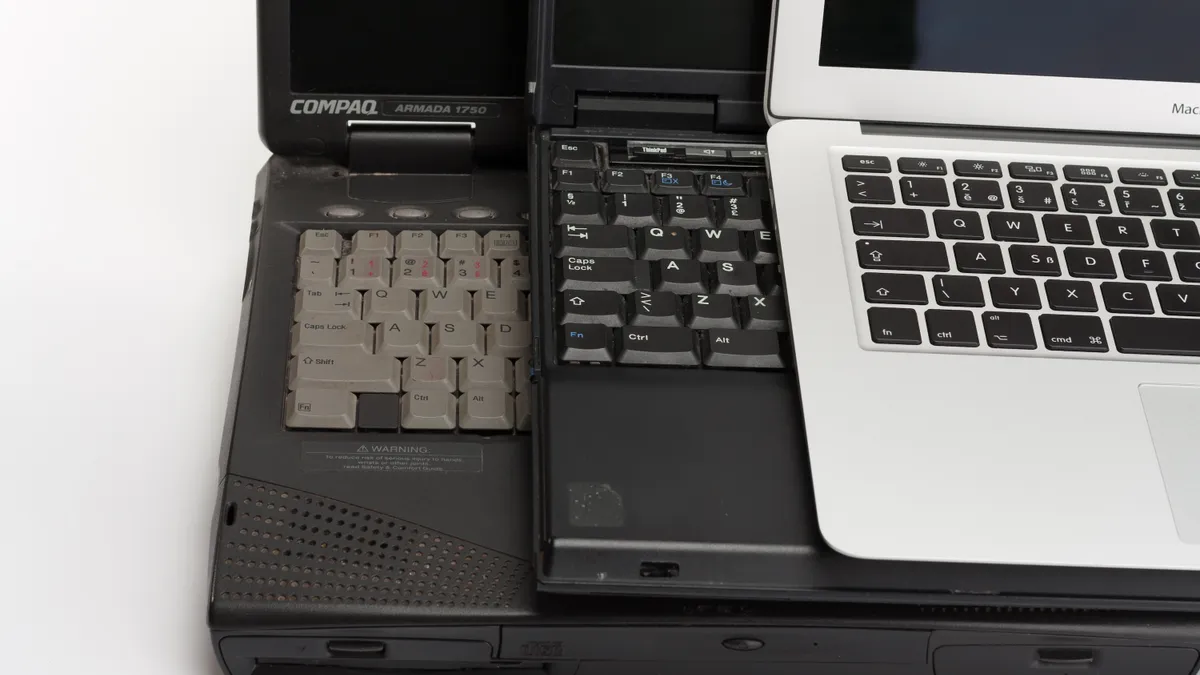

At the distribution center level, J.C. Penney has turned to new warehouse management systems and automation technology to improve operations. For example, earlier this year, the retailer installed SDI Element Logic’s Joey Pouch sorting system at a facility in Reno, Nevada, in an effort to improve inventory management and purchase delivery times.

Bala said the turn to automation is meant to eliminate an overabundance of time-consuming manual processes and handoffs that were prone to error. She added that automation technology is meant to help augment employees’ work to make their jobs easier.

“Like induction and picking and everything is much more modern and automated. You still have people doing it,” Bala said. “You still have somebody who is having to connect the dots, but it takes that manual handoff out of the picture, and it takes time out of the picture.”

Since implementing automation technology at the Reno distribution center, Bala said speed and productivity have improved at the facility, as has the time it takes to deliver to customers.

You still have somebody who is having to connect the dots, but it takes that manual handoff out of the picture, and it takes time out of the picture.

Sharmeelee Bala

Chief Information Officer at J.C. Penney.

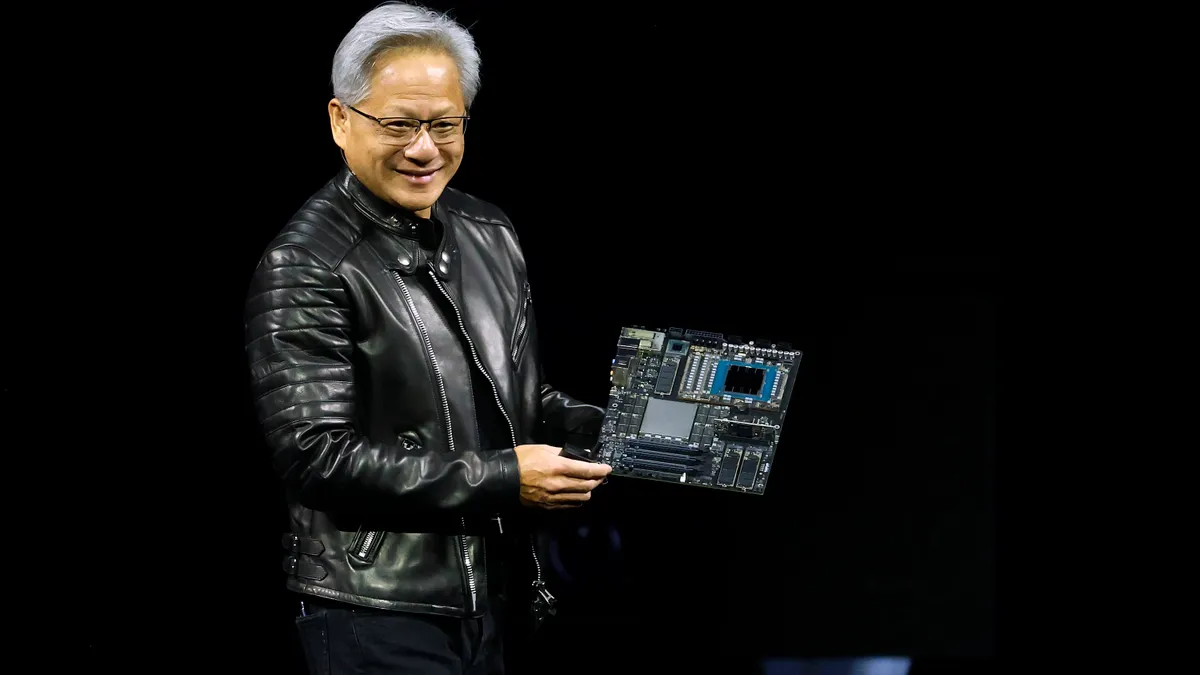

Distribution center upgrades are just part of the equation for Bala, who said one of her key challenges is upgrading a massive legacy supply chain made up of multiple systems that perform similar functions.

“I do have infrastructure that is great and stable, but they are pretty old,” Bala said. “So how do I modernize [and] at the same time invest in a way that when I modernize it, I’m also getting efficiency and not just focus on modernizing?”

Although Bala says J.C. Penney is not going after “every shiny object” available, the retailer is prioritizing AI and machine learning-enabled technology. To ensure the success of such systems, Bala has prioritized building up the retailer’s enterprise data platform. Much of that work involves consolidating and cleaning data from across the business to ensure every department is speaking the same language and working together, according to Bala.

Beyond implementing improved data hygiene practices, Bala and her team are also building a data platform that can adjust as new information comes in, allowing AI models to become more effective and provide the benefits the company needs to compete in an increasingly competitive retail arena.

“When I look at the total cost to serve, because that’s something that as a CIO, I have to keep looking at my ecosystem and say, ‘How do I make it more efficient for me to serve my business partner?’” Bala said. “How do I look at it as ensuring that we are building for the future and not just for today?”

This story was first published in our Operations Weekly newsletter. Sign up here.